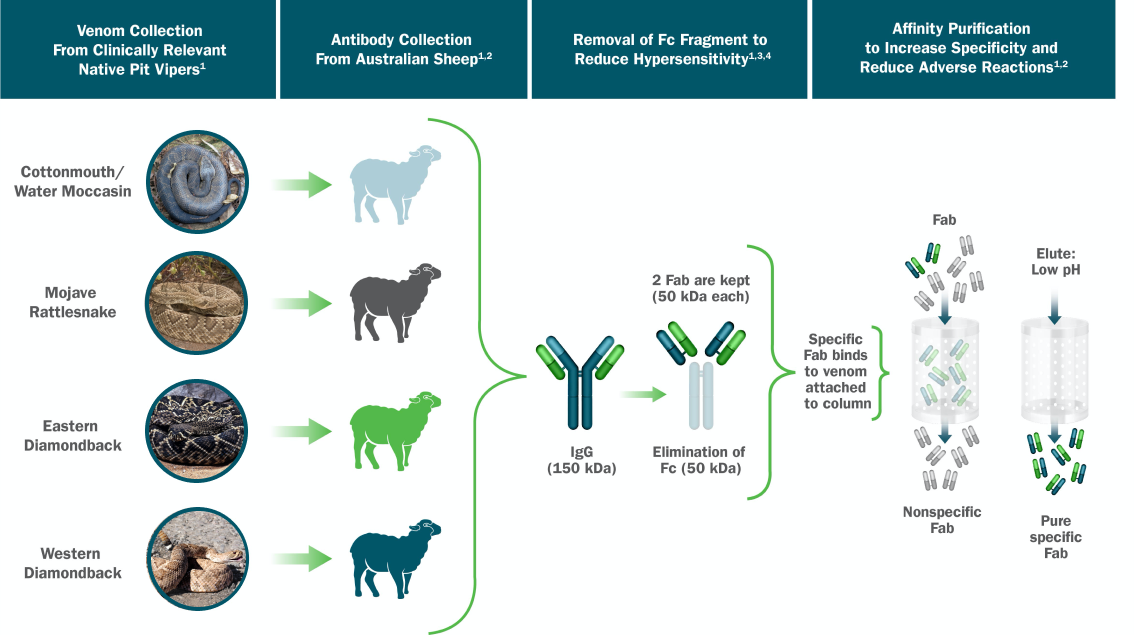

Cottonmouth/

Water Moccasin

Eastern

Diamondback

Mojave

Rattlesnake

Western

Diamondback